Forming Rollers

Forming Rollers

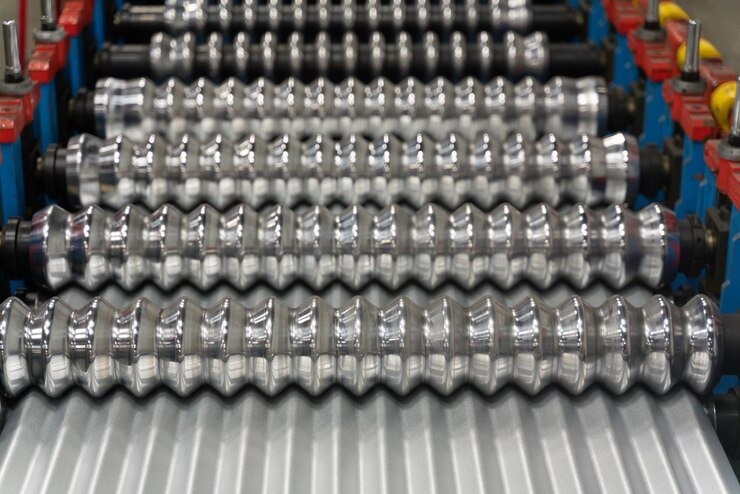

Forming rollers are a series of cylindrical rolls arranged in a specific configuration, designed to progressively shape or bend materials as they pass through. These rollers are usually made of durable metals such as steel or hardened alloys to withstand the pressure and forces involved in forming processes.

Types of Forming Rollers:

- Roll Forming Rollers:

- Used in roll forming processes, where a flat metal sheet is passed through a series of rollers to bend and shape it into specific profiles (e.g., C-sections, Z-sections, or other custom shapes).

- Often used in the production of parts for automotive, construction, and home appliances.

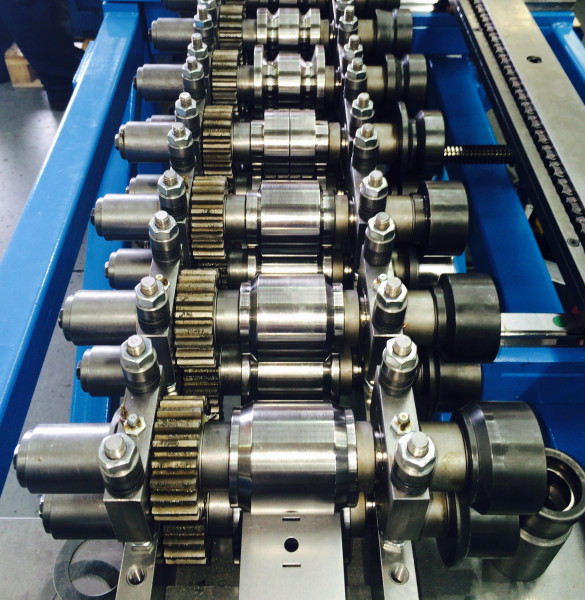

- Tube or Pipe Forming Rollers:

- These rollers are employed in tube and pipe manufacturing, where they gradually shape a flat strip of material into a tubular form. The material is then welded to create a continuous pipe or tube.

- Profile Rollers:

- Used for shaping and profiling metals into custom shapes. Profile rollers are commonly employed in industries such as construction, for items like roofing sheets, structural sections, or decorative metal trims.

- Bending Rollers:

- Specifically used for bending metal plates or bars into desired arcs or angles. These rollers are often found in the metalworking and construction industries.

Key Applications:

- Roll Forming: A process in which a metal sheet is fed through a series of rollers that progressively shape it into a desired profile. Used for creating channels, trim pieces, and other structural elements.

- Profile Rolling: Involves forming metal into complex shapes such as beams, angles, or channels. These profiles are used in structural applications, like in the construction of buildings or machinery.

- Tube and Pipe Production: Rollers are used to shape flat metal strips into cylindrical forms, which are then welded to produce tubes and pipes for various industries, including plumbing, automotive, and construction.

- Metal Bending: In industries requiring curved metal parts, forming rollers help in bending sheets or bars into precise arcs, typically used in the automotive or aerospace sectors.

Advantages of Using Forming Rollers:

- High Precision: Forming rollers offer high levels of accuracy in shaping materials.

- Efficiency: Roll forming and other processes using rollers can handle continuous production at high speeds, making them suitable for mass production.

- Consistency: Roll forming and similar techniques create uniform shapes and profiles, ensuring consistent quality across large batches.

- Customization: Roll forming systems can be customized to create a wide variety of shapes and sizes depending on the design of the rollers.