Crane Parts

Crane Parts

Crane parts are the components that make up a crane, allowing it to function and perform lifting, hoisting, and moving tasks. There are different types of cranes, such as mobile cranes, tower cranes, and overhead cranes, each with a set of parts suited to its design and function. Here are some common crane parts that we manufacture:

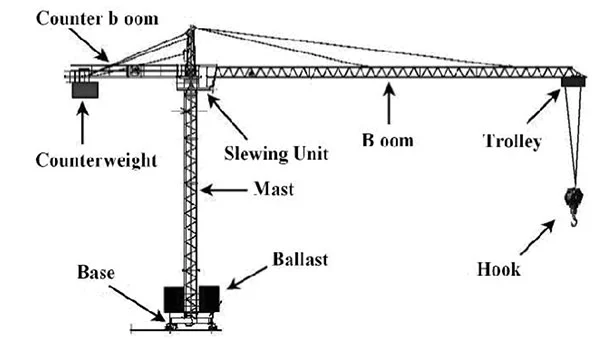

- Boom

- The boom is the long, extendable arm of the crane, used for lifting and extending loads. It can be fixed or telescopic, depending on the crane’s design.

- Hoist

- The hoist is the mechanical component that lifts the load, often involving a drum or winch. It works in tandem with a wire rope or chain to raise or lower materials.

- Hook

- A hook is attached to the hoist and is used to secure the load. It is typically made from strong, durable steel.

- Counterweights

- Counterweights are added to the crane to balance the load and prevent tipping. These weights are typically found at the rear of the crane.

- Outriggers

- Outriggers are extendable supports that stabilize the crane during operation, especially when it is lifting heavy loads or operating in difficult terrain.

- Cab

- The cab is where the crane operator controls the crane. It houses the controls, displays, and safety equipment. The location of the cab can vary, such as in the center of the crane or elevated.

- Turntable

- The turntable allows the crane’s upper structure (superstructure) to rotate 360 degrees for better maneuverability. This part is crucial in mobile and tower cranes.

- Rotating Platform (Slewing Ring)

- The rotating platform allows the crane’s superstructure to turn. It’s typically a large, circular component that enables rotation and stability.

- Trolley

- A trolley is a component that moves the hoist or lifting mechanism along the length of the boom. It can travel horizontally along the crane’s arm.

- Winch

- A winch is a mechanical device used to wind or unwind the crane’s lifting cable, helping to raise and lower loads.

- Rotating Platform (Slewing Ring)

- The rotating platform allows the crane’s superstructure to turn. It’s typically a large, circular component that enables rotation and stability.

- Trolley

- A trolley is a component that moves the hoist or lifting mechanism along the length of the boom. It can travel horizontally along the crane’s arm.

- Winch

- A winch is a mechanical device used to wind or unwind the crane’s lifting cable, helping to raise and lower loads.

- Cable or Chain

- The cable or chain is used to connect the hook to the load. It is critical in the lifting process and is made of high-strength materials.

- Pulleys

- Pulleys are used in the crane’s lifting system to change the direction of the load’s path or to help reduce the amount of force needed to lift a load.

- Jib

- The jib is an extension attached to the crane’s main boom to increase the reach or lifting height.

- A-frame (for some cranes)

- The A-frame provides support to the crane structure and helps distribute the load more evenly.

- Spreader Bar

- A spreader bar is a lifting device used to distribute the load across multiple points, improving load stability and safety.

- Hydraulic System

- Many modern cranes use hydraulic systems to power various parts like the boom, winches, and outriggers. It’s composed of pistons, pumps, and hydraulic fluid to transmit force.

- Drive System

- The drive system consists of engines, motors, and gears that power the crane’s mobility and lifting functions. For mobile cranes, it could be a diesel engine or electric motor.